Drywall Completed

Taping and Floating Begins

The drywall goes up quickly since they hang it with only a couple of nails to keep it in position. Then they have to come back and secure them firmly to the studs with drywall screws. As you can imagine, this process takes a little while, about 4 days .

Taping and floating is also expected to take a full week.

Every seam and corner gets taped and mudded and all the edges get softened with a molding. Each and every hole gets filled. Seems overwhelming but with the right tools even this small crew of two makes good progress.

This tool is a taping gun that has a roll of tape loaded in it and then filled with mud. This allows the tape to come out pre-mudded which really simplifies the process. I wish I would have had one of these for all the drywall projects I've done over the years.

We had a cool front this week with the nights dropping into the upper 40s, which made for great working conditions, however, it kept the mud from drying very quickly.

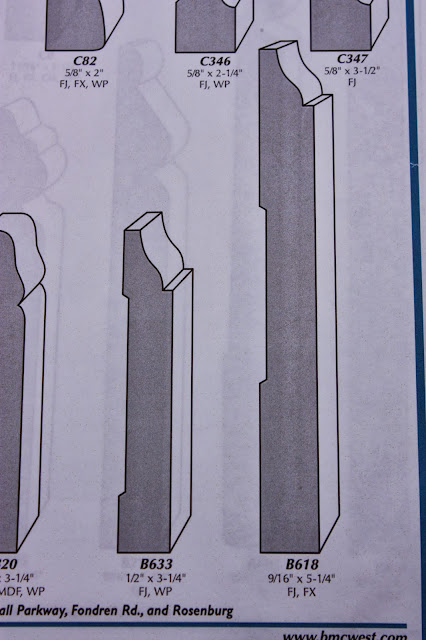

After the sharp corners and cheese grater walls in our previous home, we are looking forward being injury free in the new house. We asked for softened corners which are pretty standards these days. They use this plastic corner molding for all the edges. It is flexible too which makes it ideal for the arched doorways as well.

The mudding was nearly completed, when Uriah noticed that the washer hook ups were in the wrong place, they would have been in the middle of the laundry room counter tops. So at 5 pm we decided to fix the problem ourselves since the next day they were to begin texuing the walls. Thank goodness for Jim's Hardware just a few minutes down the road because the closest big box store is 35 minutes away. Luckily I had taken pictures of the walls before they were covered in drywall, so we were able to see exactly what we would need to do to move the laundry box.

All we had to do was move the white box over one bay to the right. If we would have noticed it when it was at this stage, it would have been a piece of cake to fix. But no, we were there fixing the problem till about 10 pm. But now Uriah will not have to fix this in the future.

The little white box is now covered by the brown paper since they were to begin texturing soon.